Automotive

While at Harman International - Automotive Division, I collaborated with several manufacturers, including Mercedes-Benz, BMW, and Porsche, to produce market-leading in-car sound systems.

The two examples below highlight some of my designs. The first example showcases a new sub-woofer grille design for Mercedes. The second example details a problem-solving project aimed at improving an existing product for BMW.

The two examples below highlight some of my designs. The first example showcases a new sub-woofer grille design for Mercedes. The second example details a problem-solving project aimed at improving an existing product for BMW.

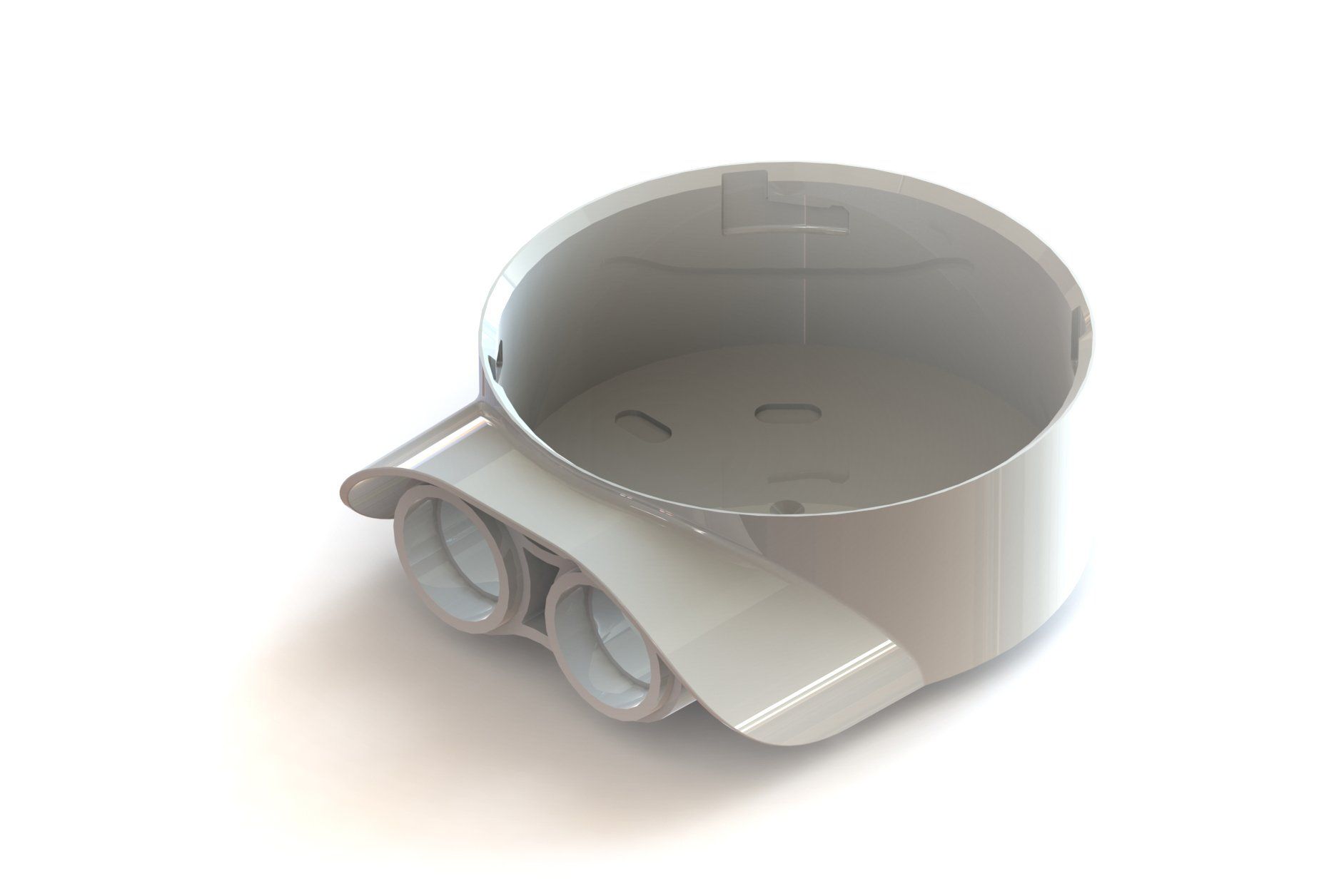

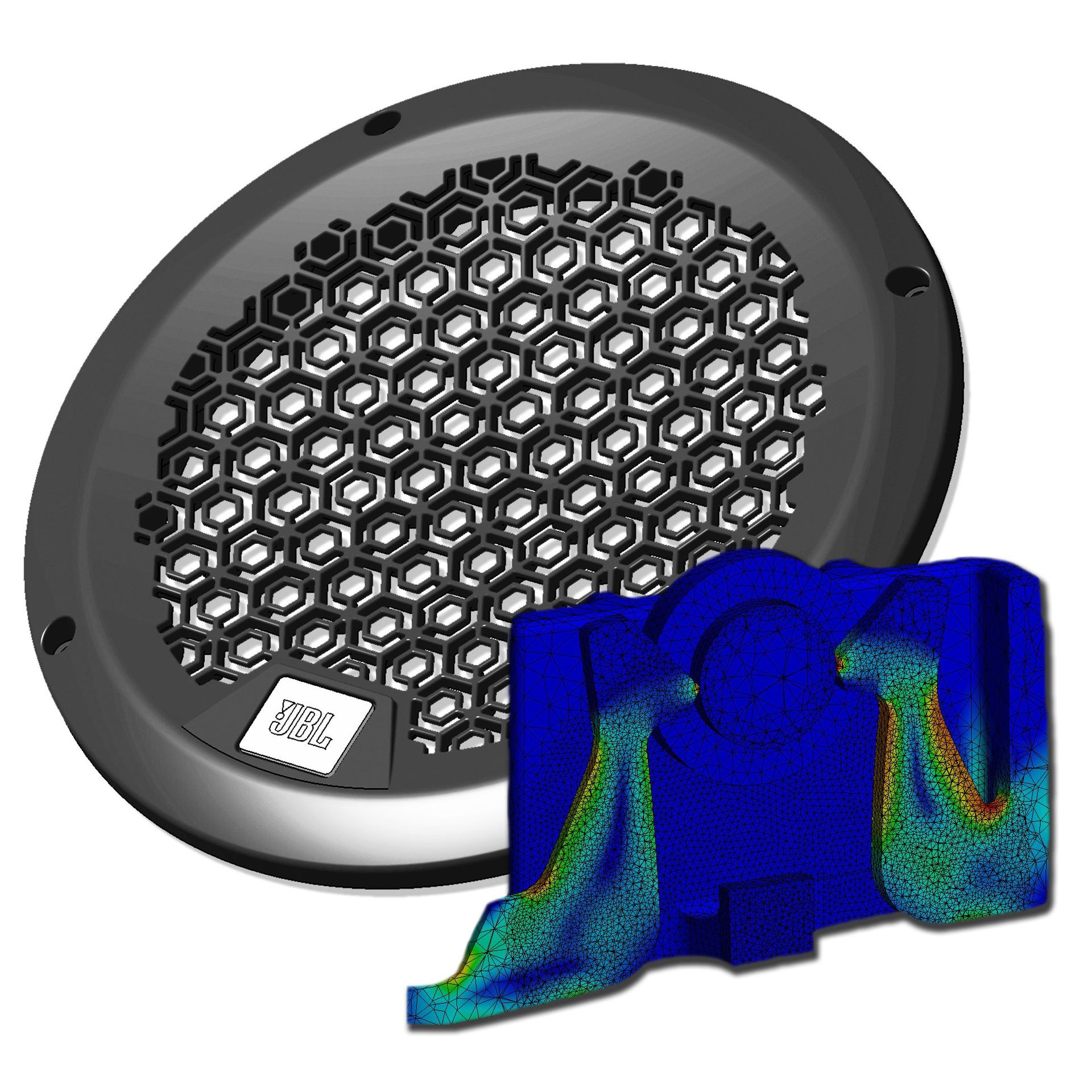

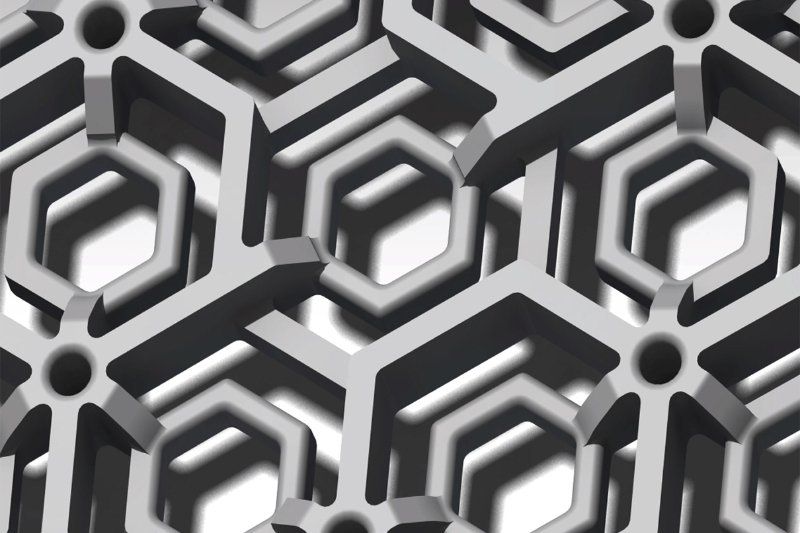

Mercedes Grille

The grille's cosmetics were supplied in the form of a rendered graphic by Mercedes. My task was to take that image and turn it into a viable product, staying as true to the original design as possible. Although the part's appearance seemed purely cosmetic, its true purpose was to protect the speaker. In this case, the grille had to withstand a load of 30N without breaking or deflecting more than 10mm.

To achieve this, I utilized the natural strength of the honeycomb pattern. To further enhance it, I added ribbing to the rear of the molding, ensuring that the cosmetic surface remained unaffected. I also redesigned the integration of the JBL

logo, resulting in savings on assembly costs.

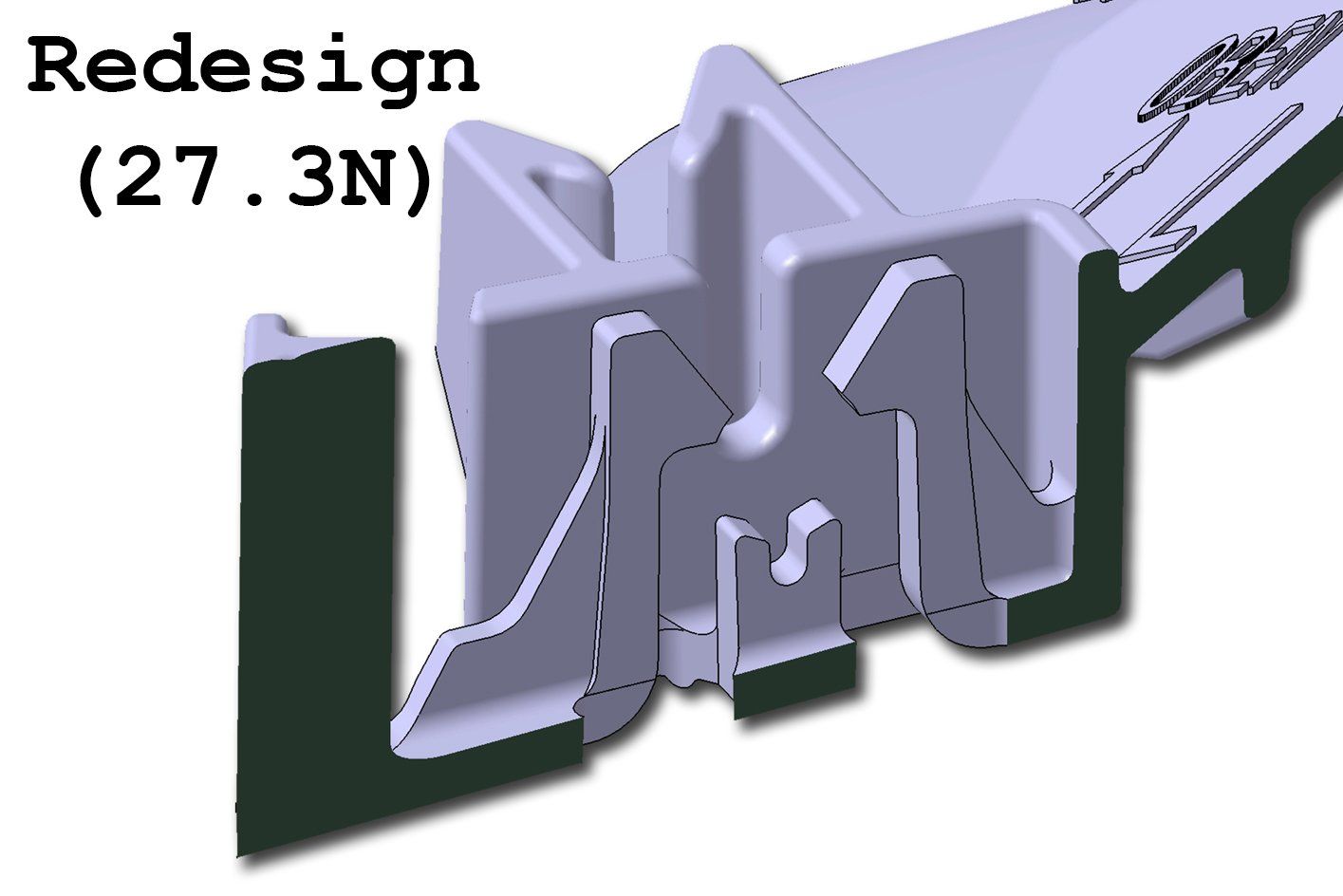

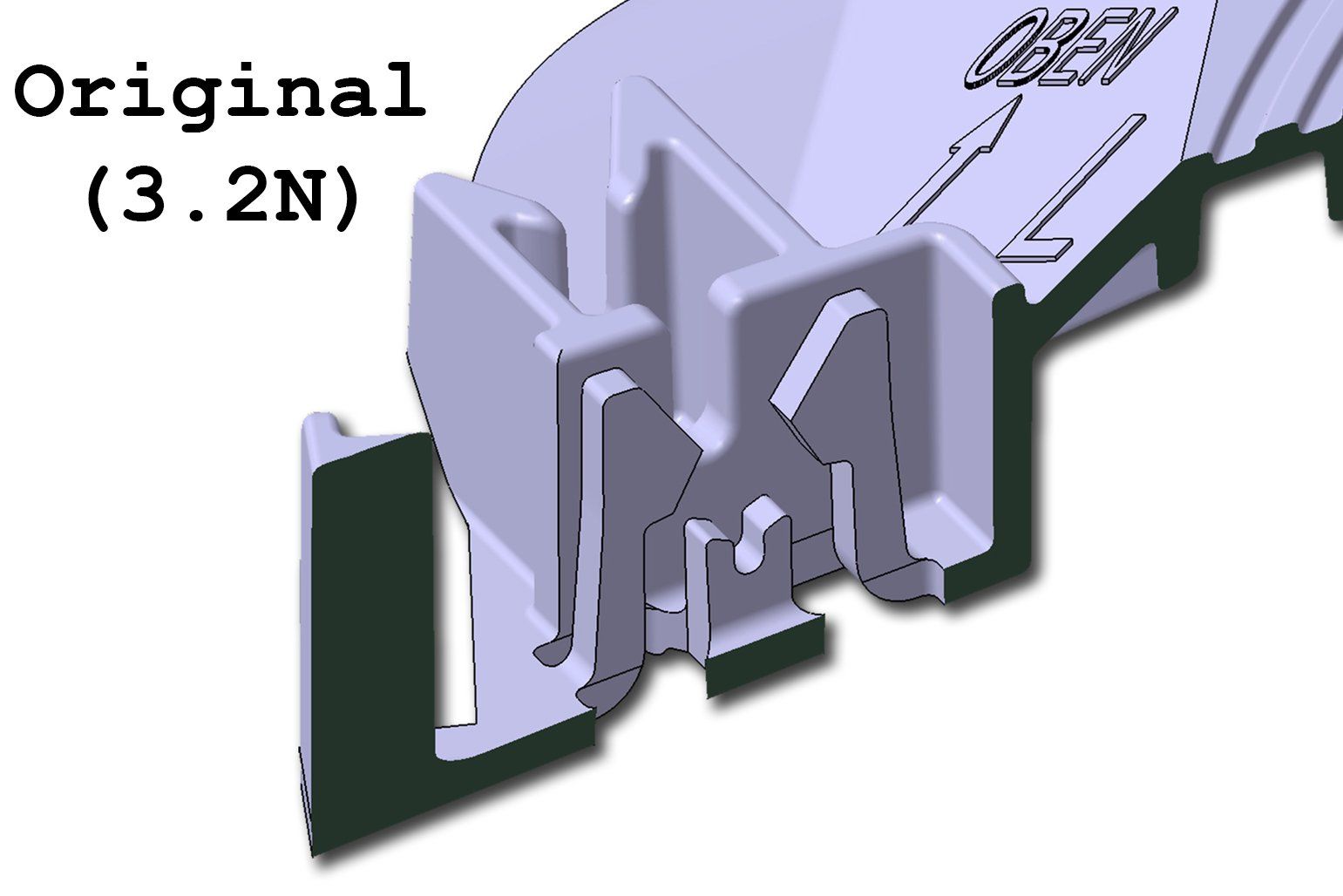

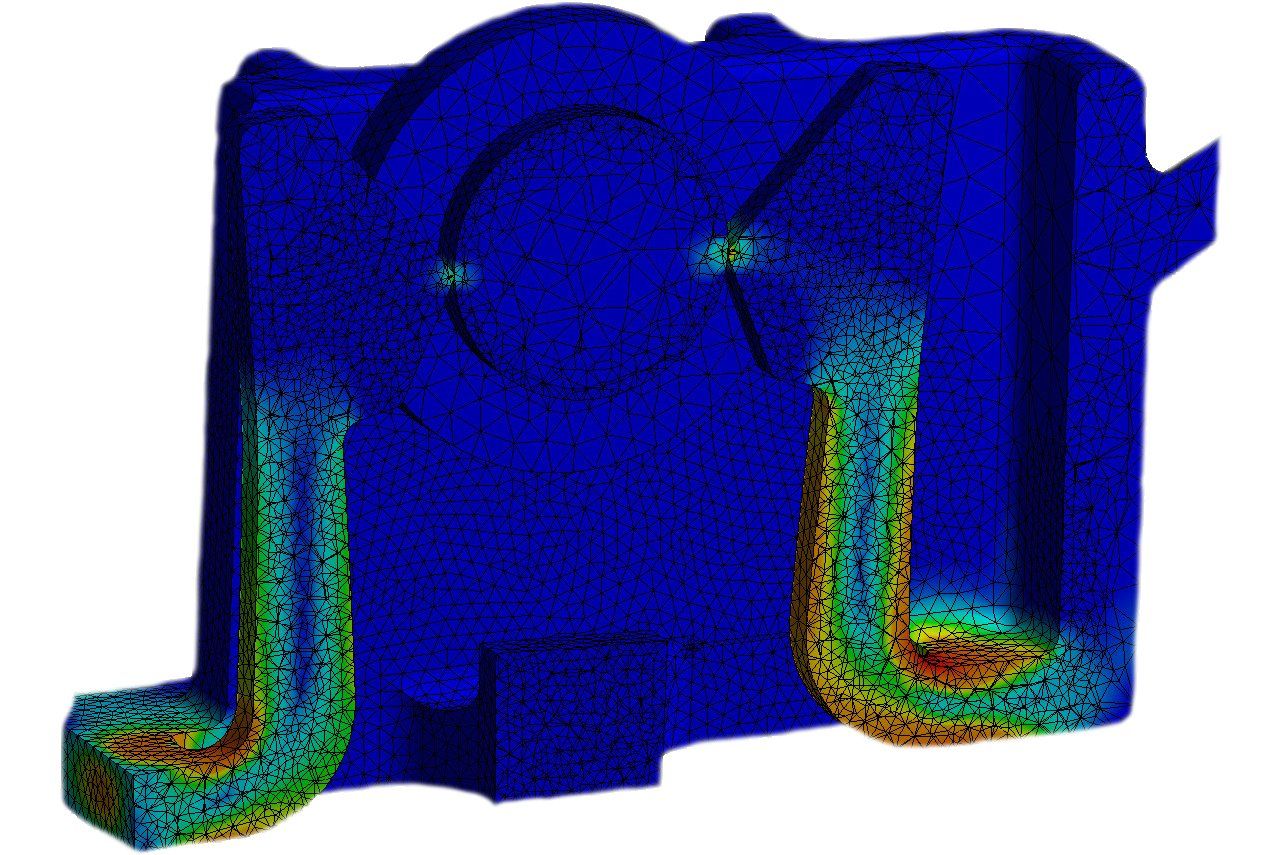

BMW Clip

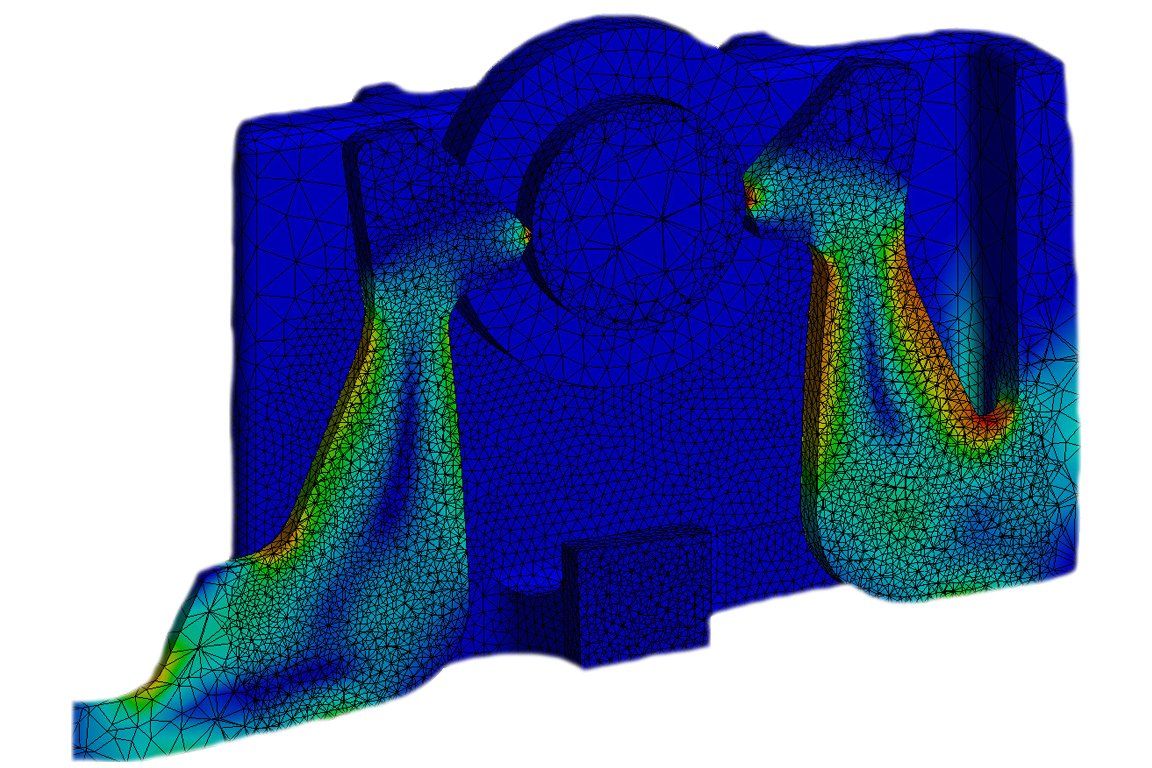

The objective of the redesign was to increase the force required to remove a cable grommet from the clips on a legacy product. This needed to be achieved with minimal impact on the part and the most cost-effective approach to injection molding tooling. The addition of extra ribbing and profile stepping increased the force required to remove the grommet by almost nine times. The design would only require metal removal from the tooling, thereby limiting costs and time scales required for implementation.

The new data was sent to BMW along with the stress analysis video. Once BMW approved and implemented the change, the issue did not recur in the marketplace.