Plastic Injection Molding

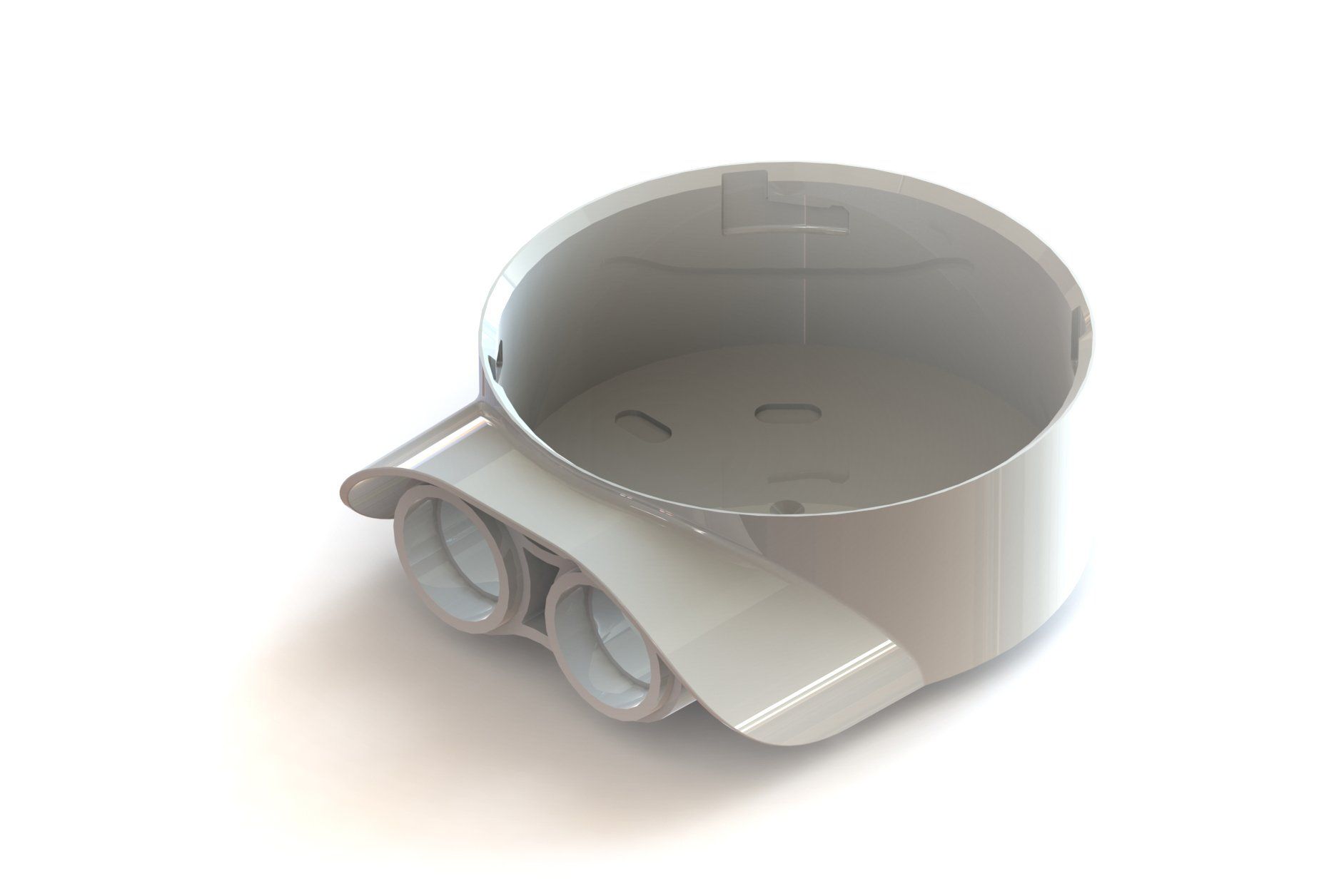

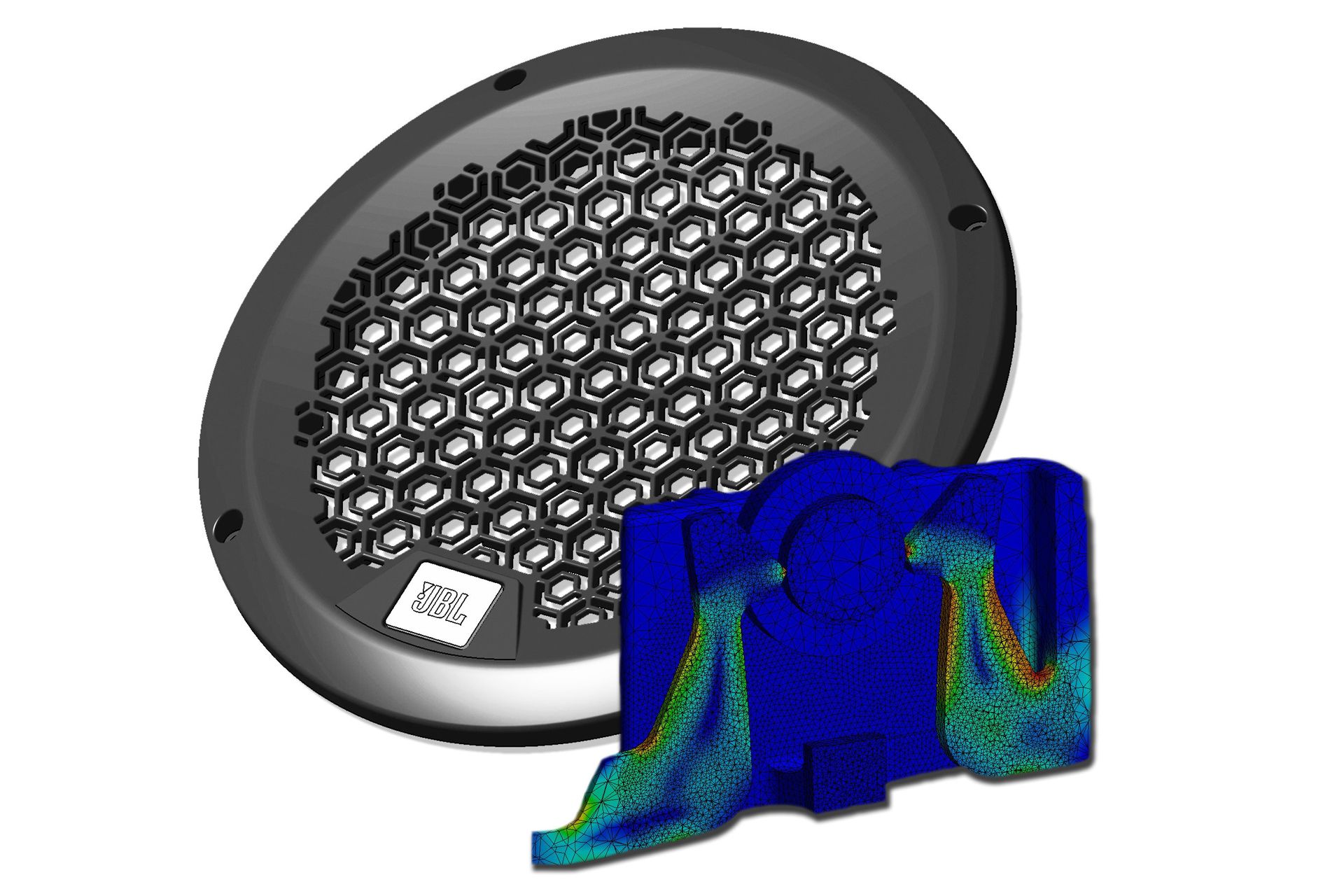

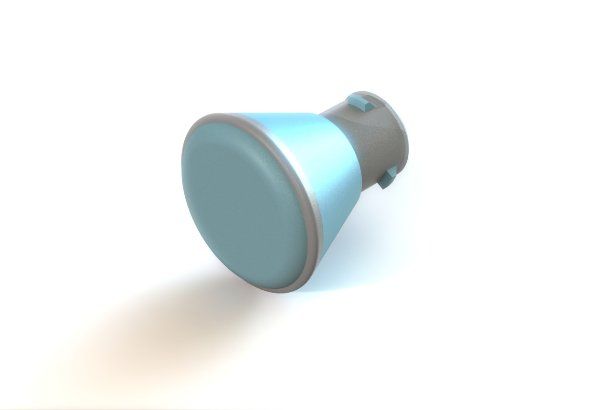

Throughout my degree and career, I have designed plastic injection-molded parts. In most cases, these parts were created to package elector-mechanical assemblies, where my qualifications in Product Design and Mechanical Engineering allowed me to seamlessly blend aesthetic requirements with the robustness needed to survive highly demanding and regulated industries. I have consistently collaborated with tool designers, whether in person, over email, or through third parties, to achieve the best possible results in terms of part quality, lead times, and tooling lifespan.

Implementing Design for Manufacture (DfM) within the company and/or with external partners always emphasizes reducing risk to achieve the best possible outcome. In the modern manufacturing world, repeatedly attempting to get the part right is no longer acceptable. Speed to market is crucial, but speed to market with a proven, working design is key. My knowledge and varied experiences enable me to consistently deliver this requirement. Below are some examples of my work.