Graphic Design

Throughout my career, I have been required to produce graphics for products, Graphic User Interfaces (GUI), literature, and simulated online products for demos. This was achieved using programs such as Adobe Illustrator, Photoshop, InDesign, and Expression Blend. This led to me setting up and overseeing the in-house printing system within Huntleigh for labels and user manuals. Below is a small overview of some of my work.

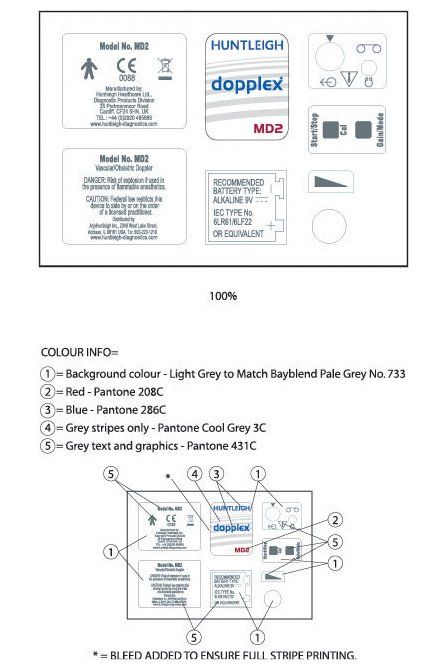

A product designer is often required to cover more than just the mechanical elements of a product. In many cases, I was required to create or contribute to user literature, product graphics, and labeling.

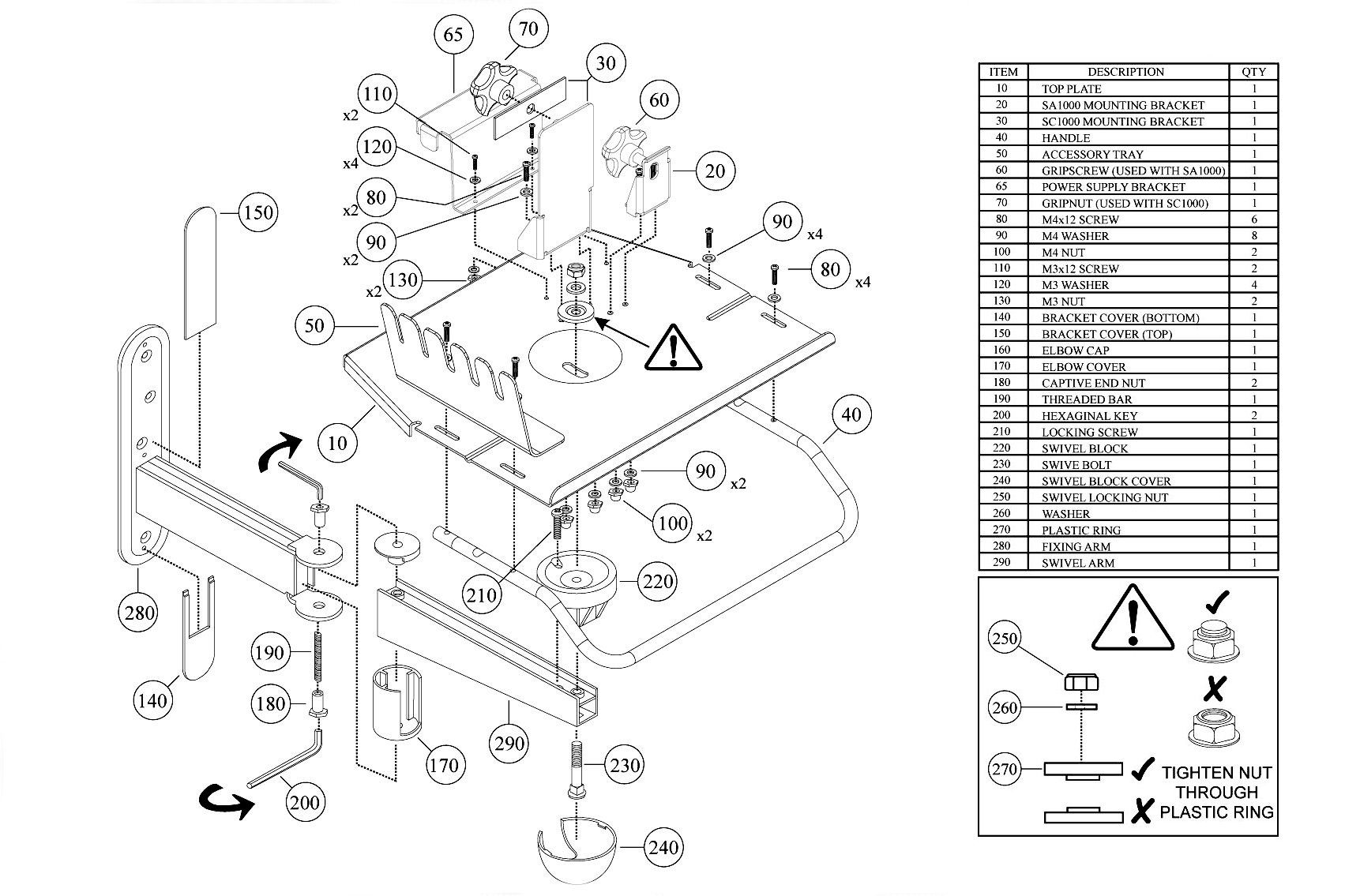

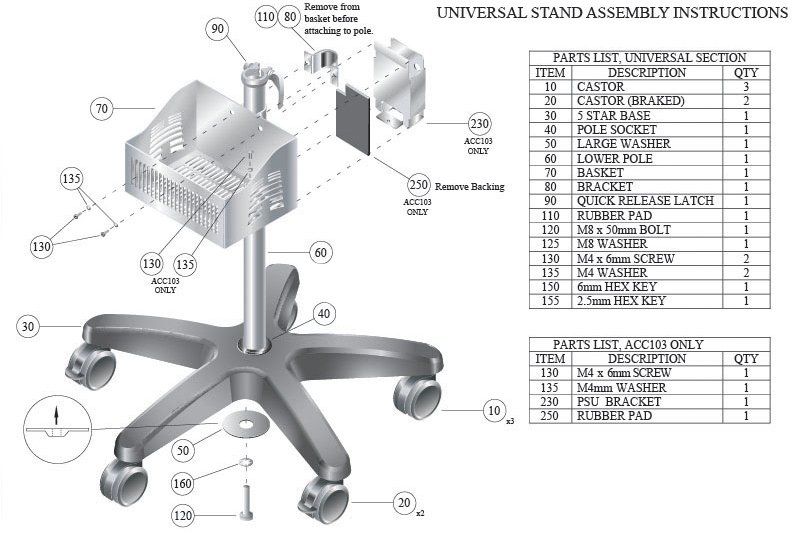

Importing CAD-generated imagery into Illustrator allowed user instructions to be created in a more time-efficient manner.

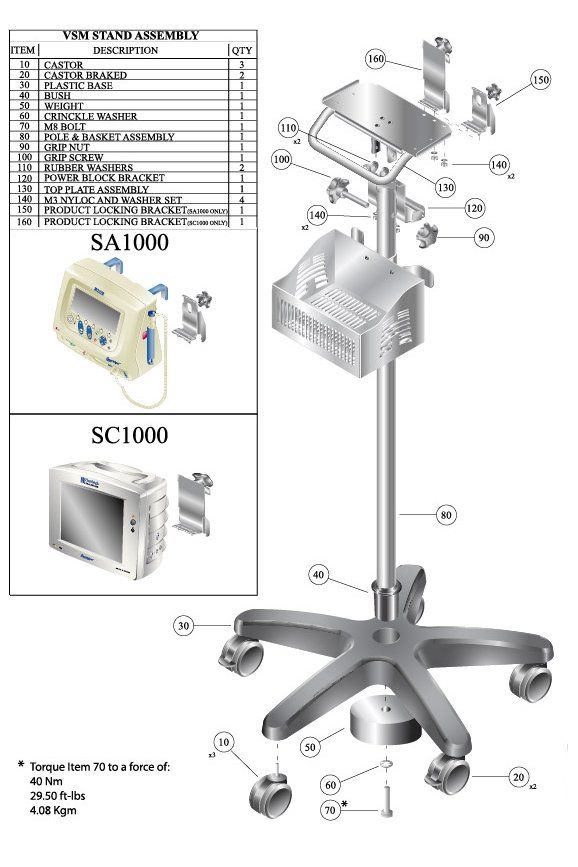

When CAD data is not available, it is often necessary to generate it in Adobe Illustrator. This includes creating outline drawings as well as fully rendering the images in a lifelike representation.

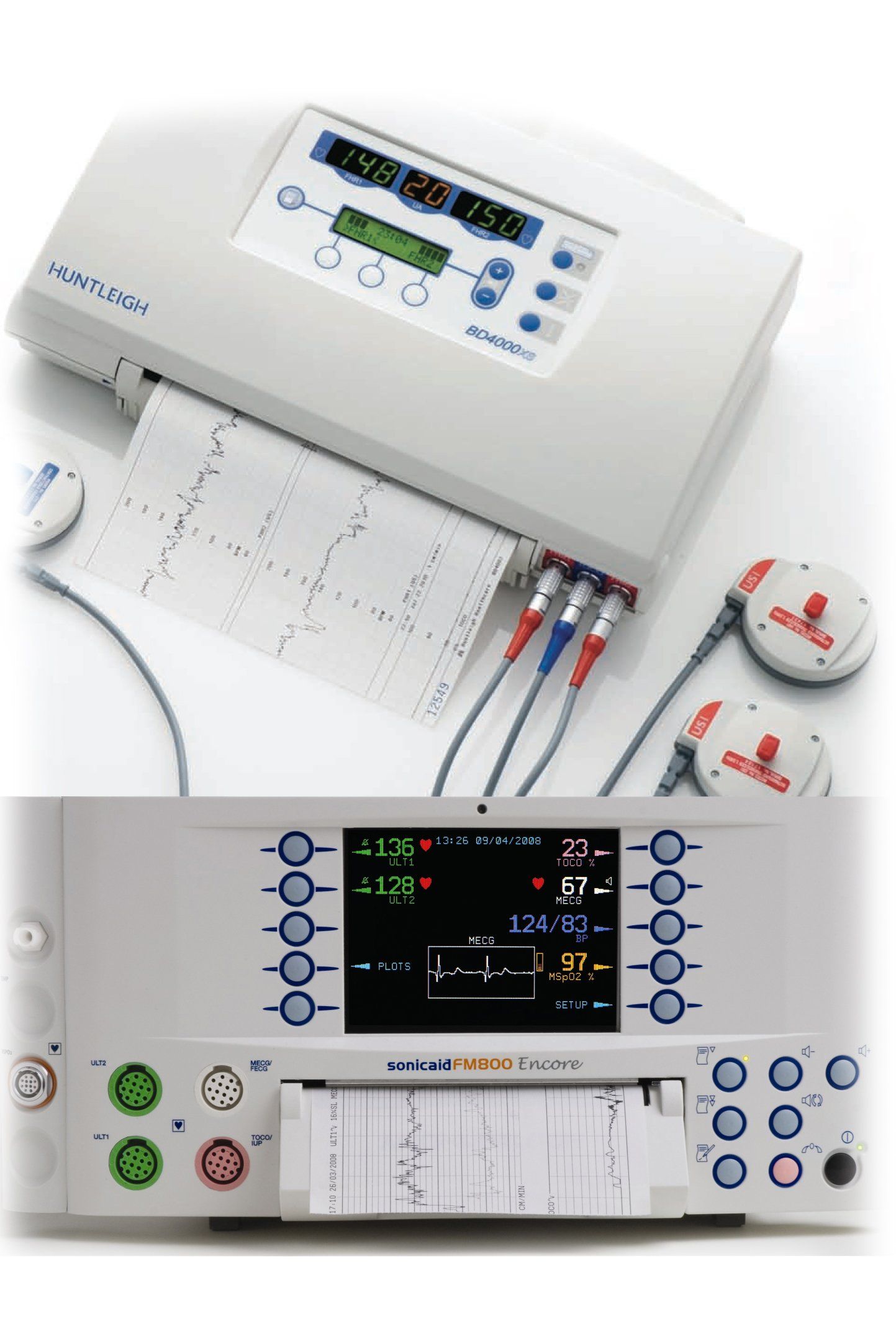

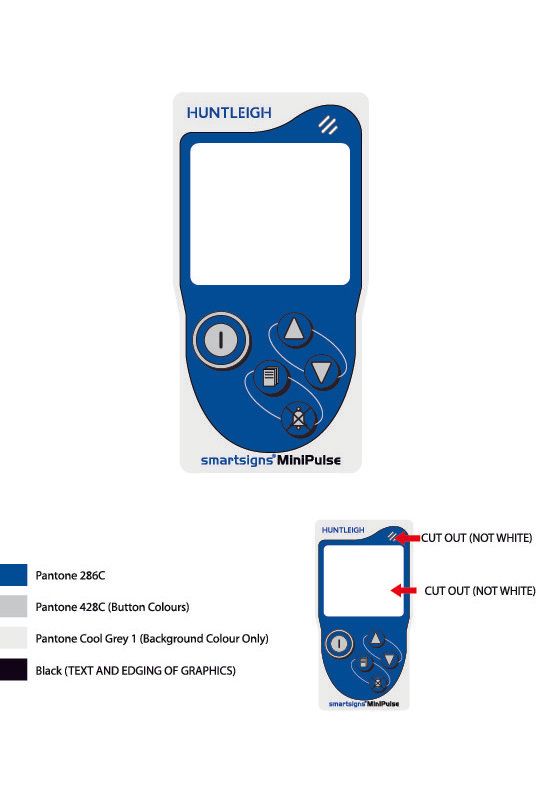

In addition to user literature, every product required some form of branding or styling to be added to the moldings. This could take the form of an inlay, label, keypad membrane, direct printing onto a molding, or a combination of these methods. In each case, a design would be developed, and final artwork generated. Two examples of my artwork can be seen to the left and right of this text.

For the Smartsigns MiniPulse (top left), focus groups initially found the original product to be dull and boxy. I was brought into the project to help improve its image. Although the tooling for the molded parts was complete and could not be changed, I had the idea to use the keypad membrane to create visual styling that tricked the eye into thinking the product itself was curved, even though it wasn't. When this was presented to focus groups, it received a 100% approval rating.

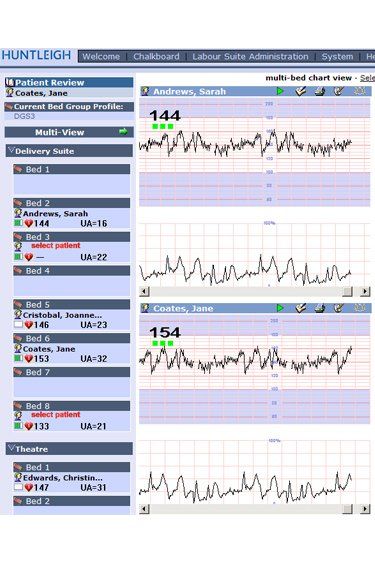

Working with software engineers, I often created the graphics they would use on embedded and platform-based products. In some cases, I generated the code myself and supplied it as a package.

For the Smartsigns MiniPulse (top left), focus groups initially found the original product to be dull and boxy. I was brought into the project to help improve its image. Although the tooling for the molded parts was complete and could not be changed, I had the idea to use the keypad membrane to create visual styling that tricked the eye into thinking the product itself was curved, even though it wasn't. When this was presented to focus groups, it received a 100% approval rating.

Working with software engineers, I often created the graphics they would use on embedded and platform-based products. In some cases, I generated the code myself and supplied it as a package.