Aerospace

STG Aerospace

is an international industry leader in the field of the development, design and manufacture of aircraft cabin lighting solutions for commercial and military sectors.

The example below shows how approaching a problem with an open mind and creative thinking a solution to a problem can always be found.

The example below shows how approaching a problem with an open mind and creative thinking a solution to a problem can always be found.

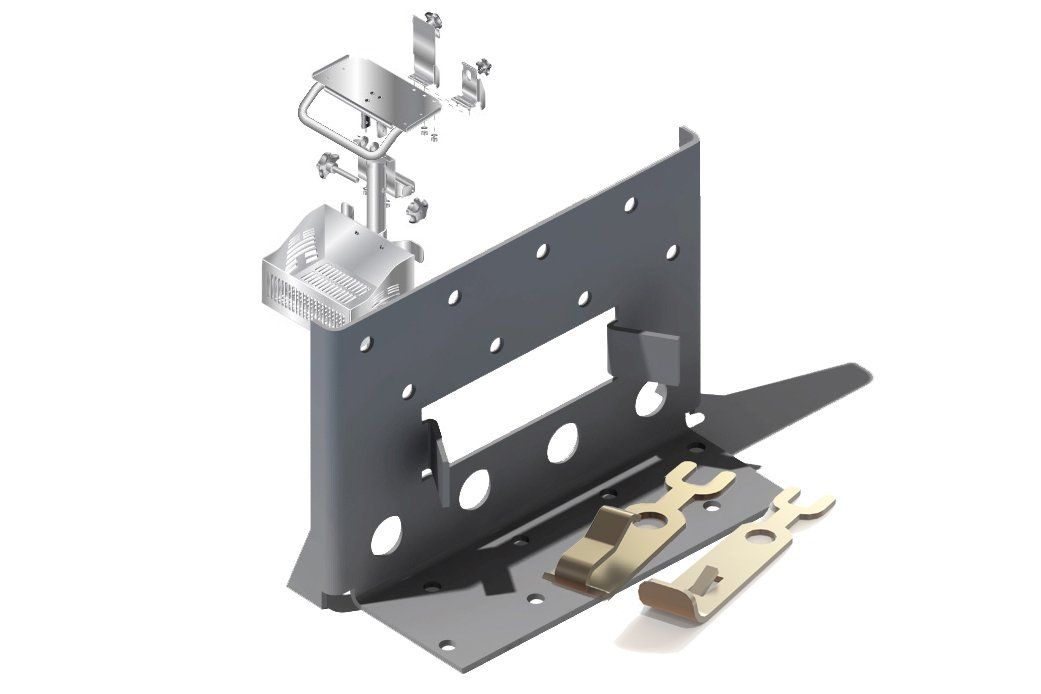

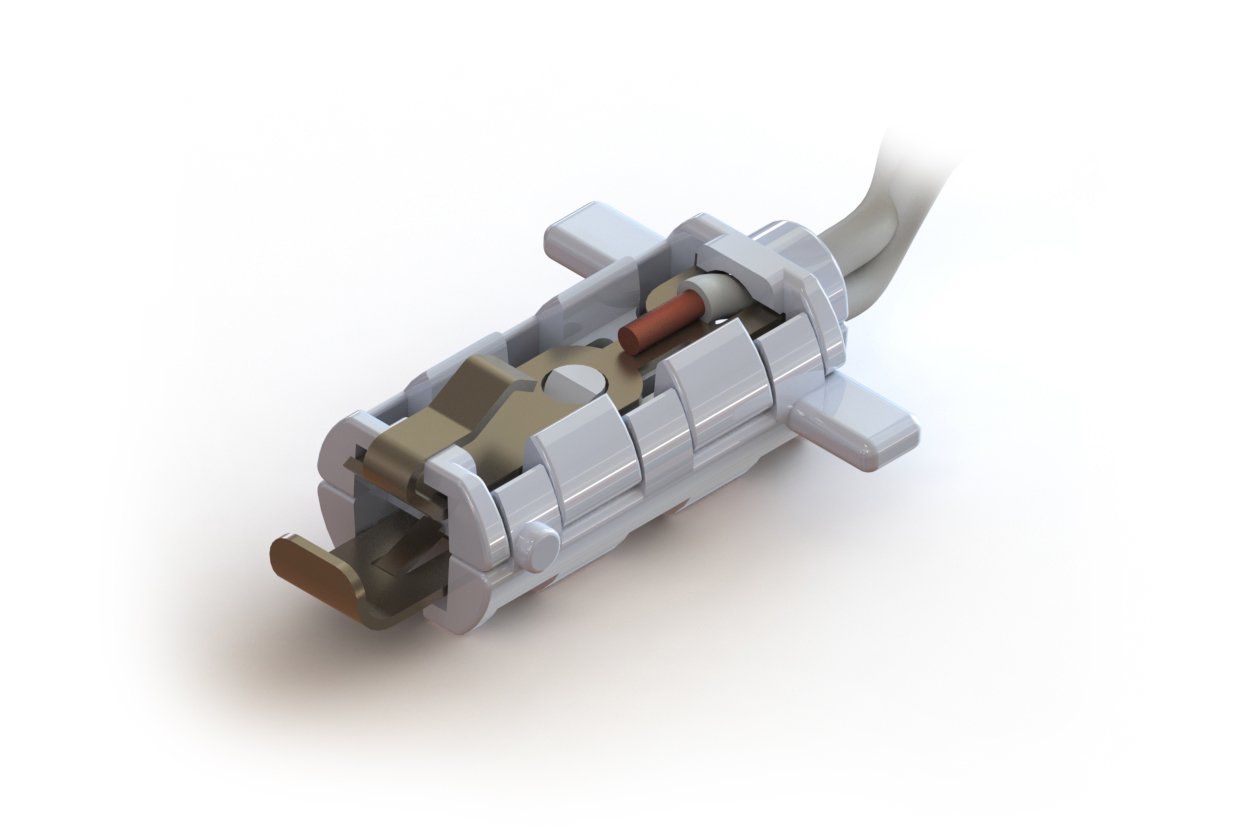

Bulb Bayonet Replacement

During a project to design a personal lighting system for the Boeing

737 and 757 fleets, a solution was required to create a new method for connecting the LED light to the existing aircraft infrastructure. The existing design used a standard incandescent bulb, which would not be used in the new design. Therefore, a method was needed to recreate the connection method of the bulb while adhering to modern safety and Design For Assembly (DFA) standards.

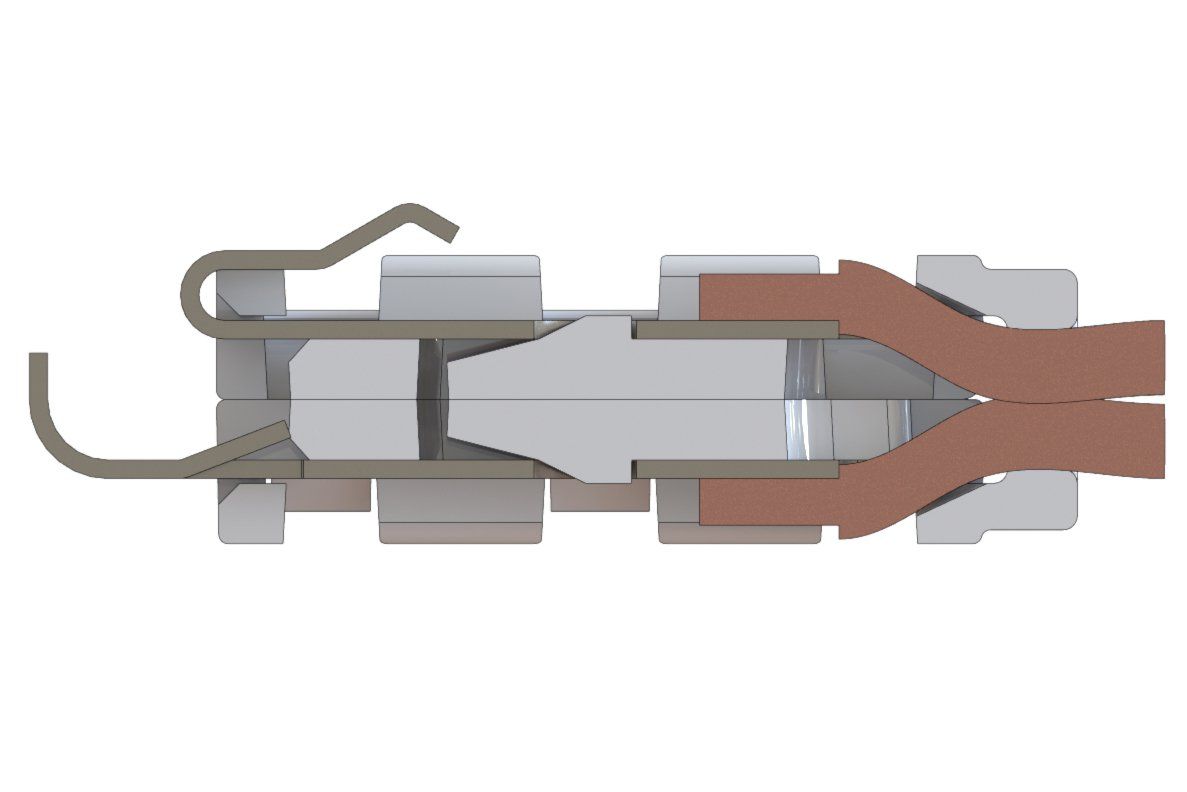

During the risk review, it was identified early on that any new design had to include extra insulation from the power source, considering there would be no glass bulb to hold during fitting. To address this, I decided to use a combination of metal and plastic parts.

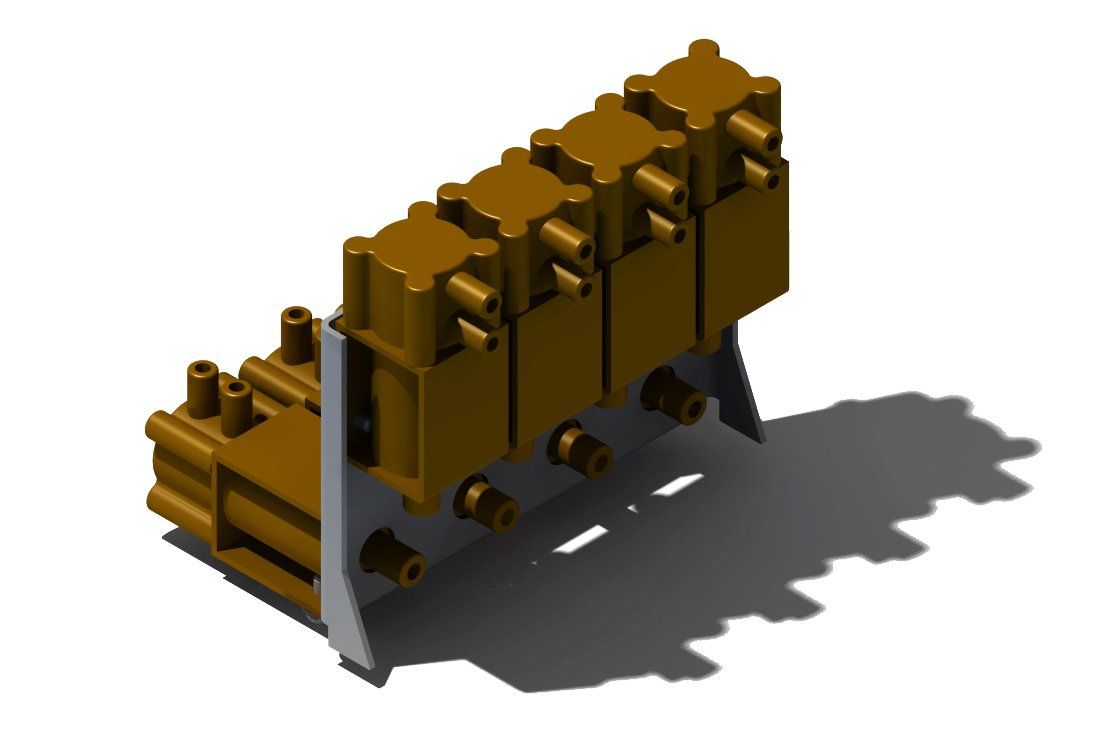

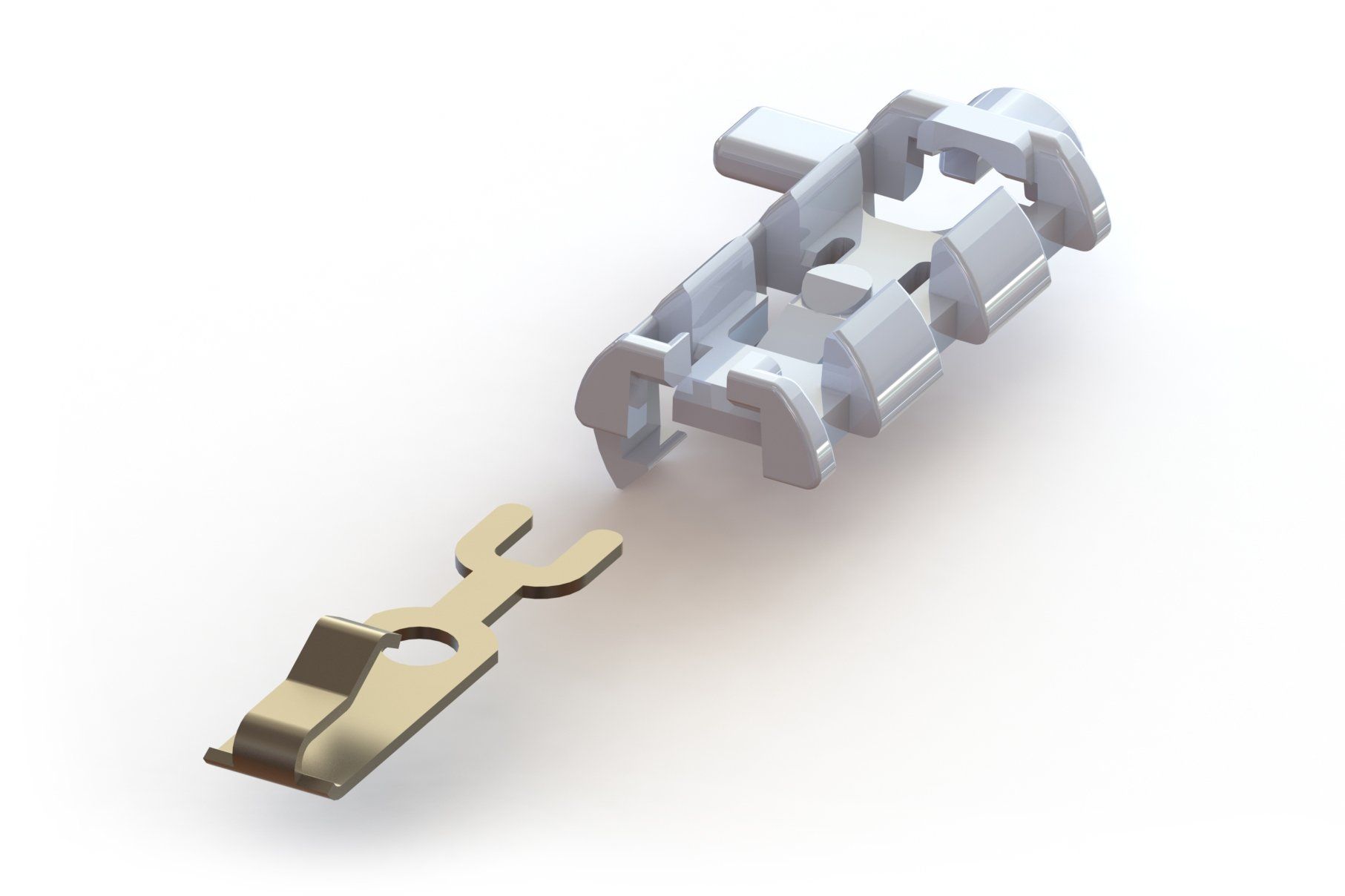

The metal contacts were designed to emulate the mating points found on the existing bulb. Using sprung steel with a copper-nickel finish, the contacts were held in place by a plastic carrier. The carrier molding could be used for both styles of contact mentioned above. One contact was designed to carry the ground signal, while the other carried the power.

On both contacts, I designed a "Y" shape ending to accommodate the wire that feeds the main lighting assembly. The wire would be soldered to the narrow section of the "Y." I kept this section as narrow as possible to limit heat dissipation through the metal connector, ensuring a good solder joint. Once the wires were attached, the connectors were designed to slide into the plastic housing and lock in place.

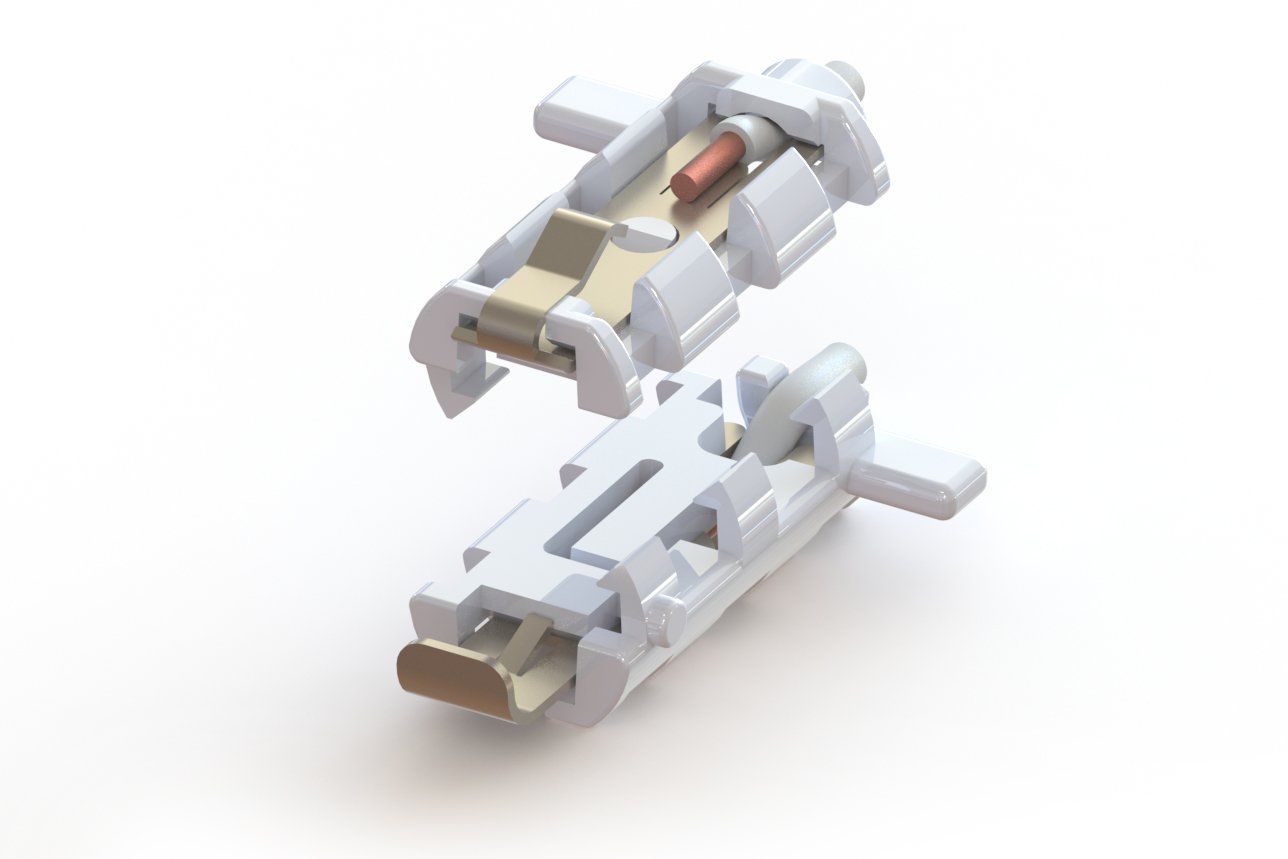

The animation demonstrates how two sub-assemblies were created and then snapped together to form the final bulb bayonet replacement assembly. Notably, the main body of the assembly was only 8mm in diameter.